Related Projects: Servo-Actuated Ball Valve

Role: Responsible Engineer

Requirements: Develop a bolted closure pressure vessel for storing Nitrous Oxide at a designed burst factor of 2x.

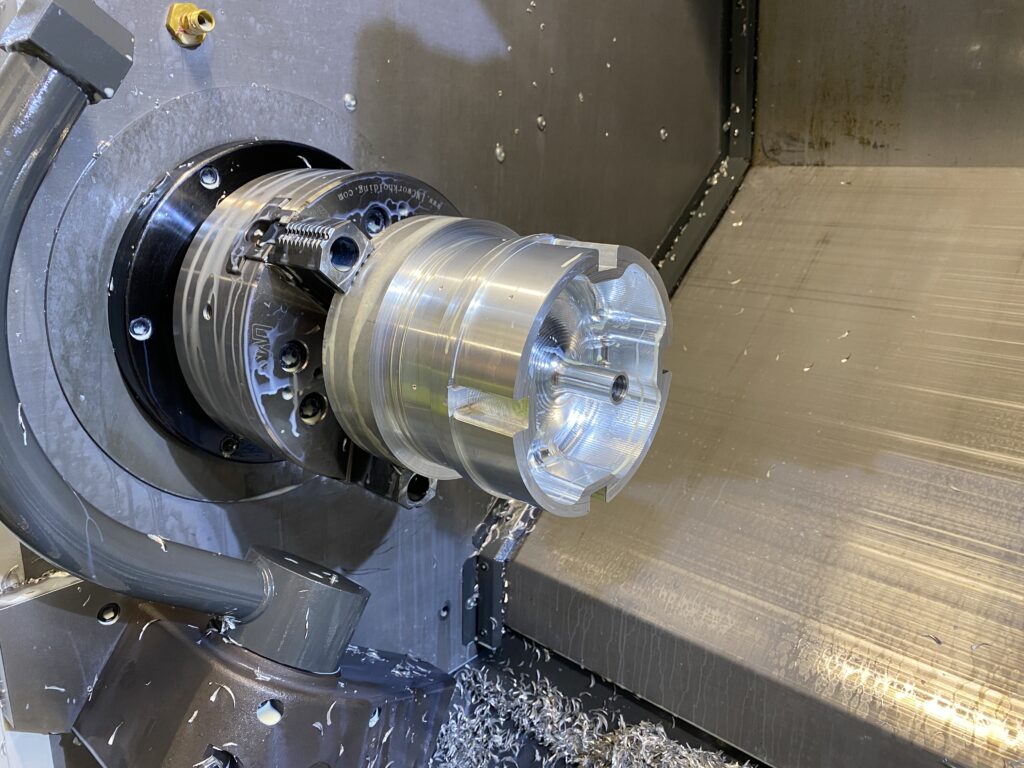

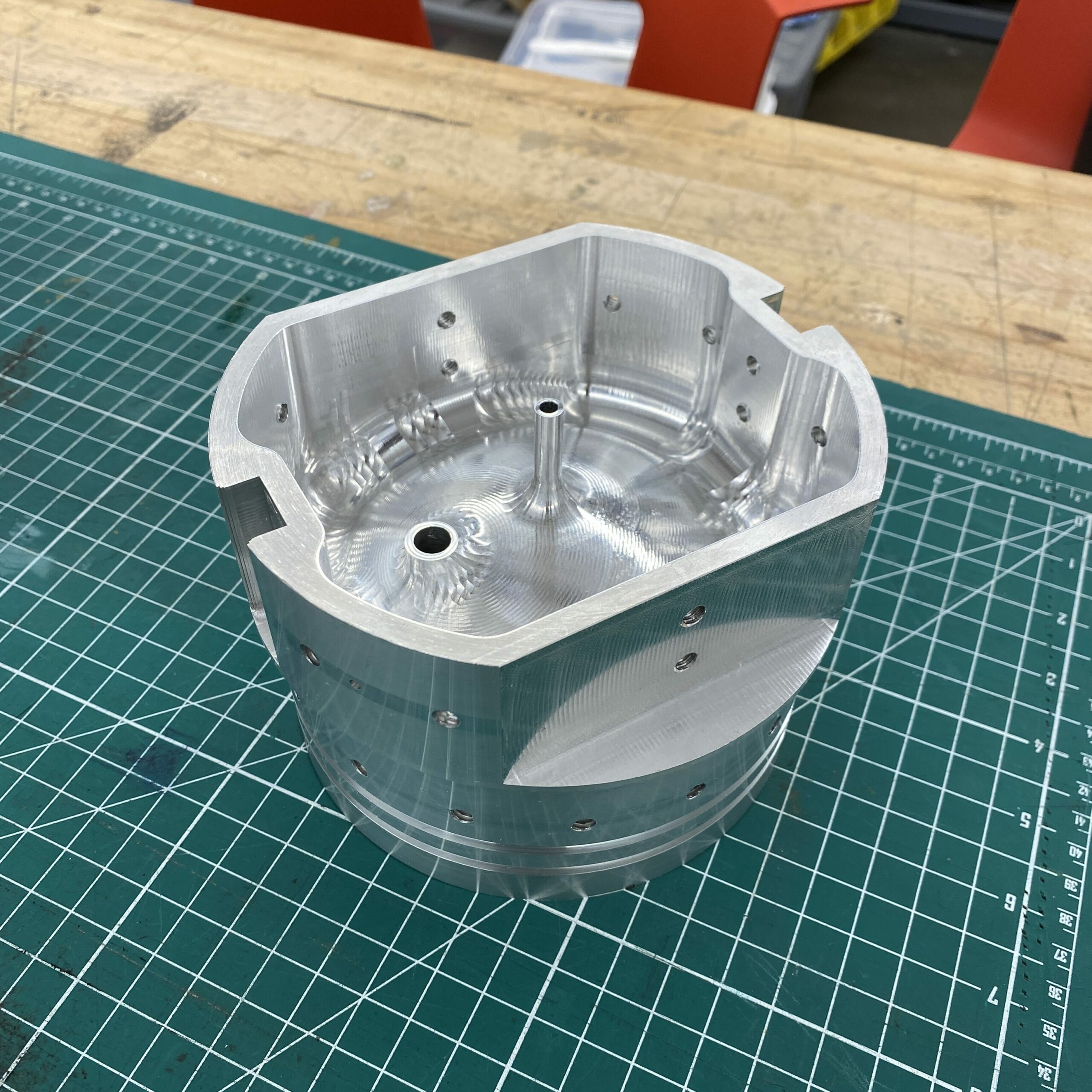

Summary: The first iteration of the end caps was manufactured over a 4-week period on a Haas ST-20Y and Haas 3-axis mill after using Fusion 360 to CAM it.

Unfortunately, hydrostatic testing was a failure. Our oxidizer tank failed at 600 PSI, less than the 750 PSI needed for a nominal launch and nowhere near the factor of safety needed to pressurize with a compressible gas (1.5x).

The root cause of the failure was not fully accounting for bearing stress and the bolts retaining the end cap. It emphasized the importance of two programatic principles I’ve since taken to heart:

- Test early and often: Hydrostatic testing safely exposed a critical design flaw that would’ve otherwise served as an even bigger program setback.

- Build in schedule margin: Projects rarely go to plan, building in schedule margin helps prevent project setbacks from becoming program blockers.

Within a week, we reworked the analysis and remanufactured the tank.

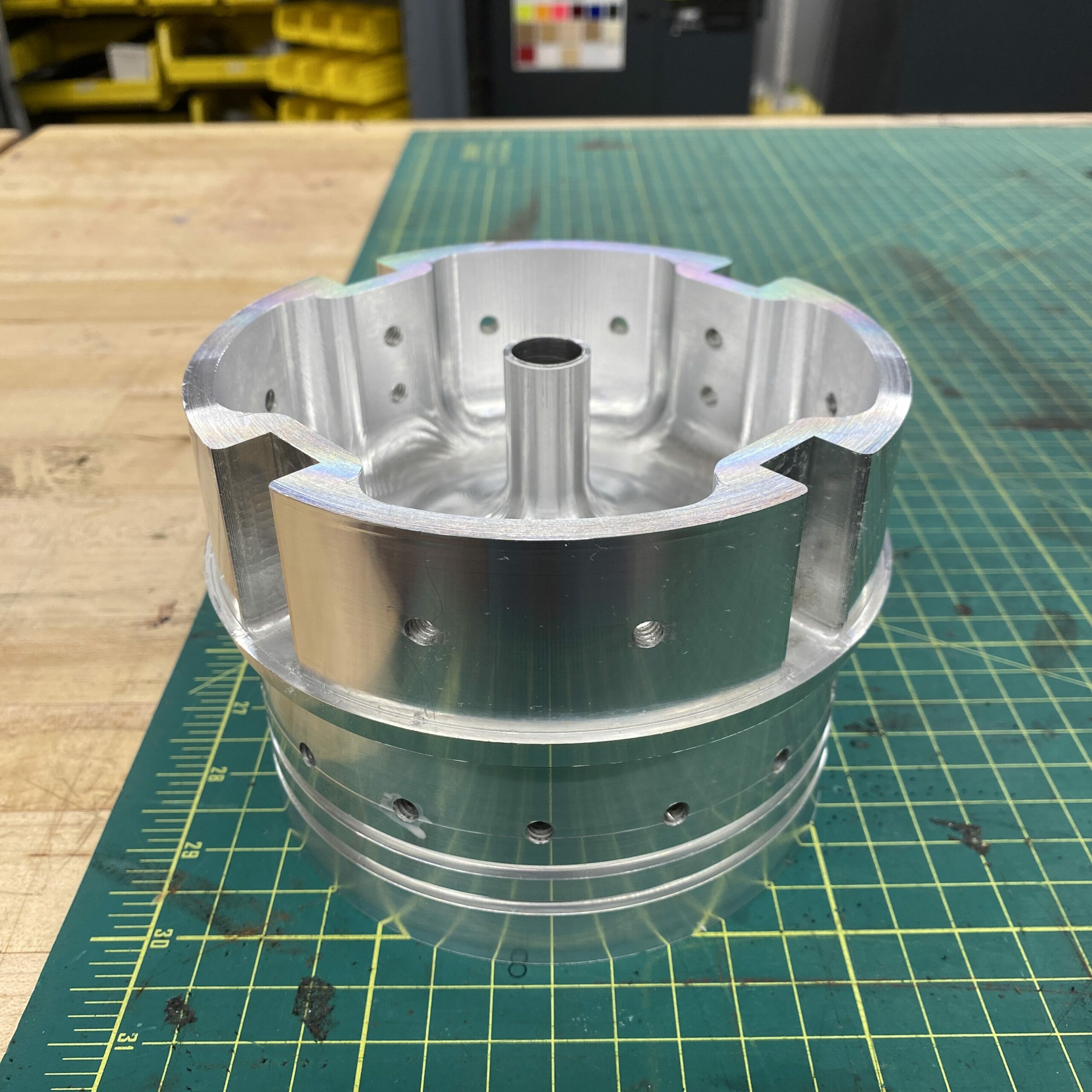

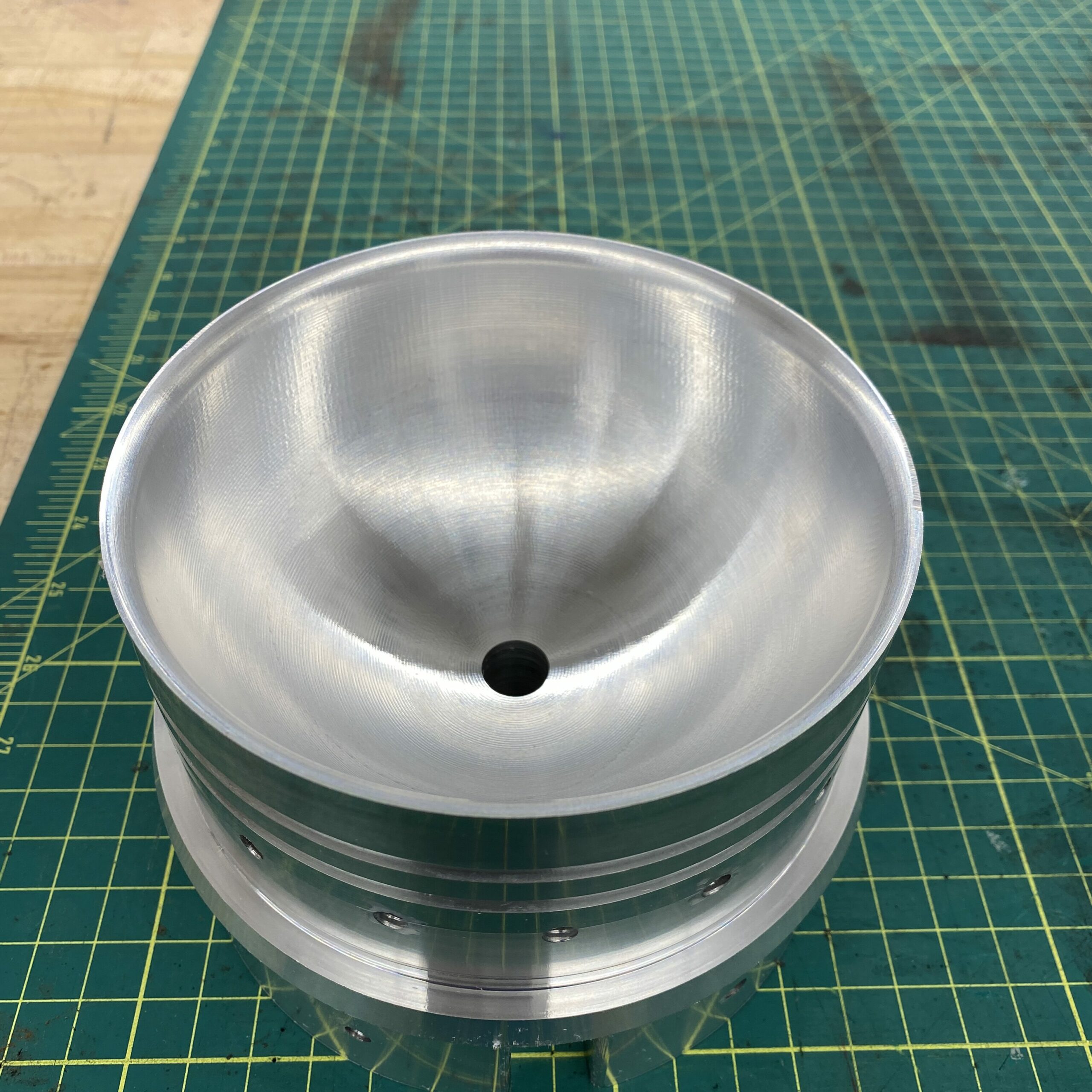

The new end caps were designed and manufactured within a week. Additionally, the quality of machining improved with experience.

Using some clever workholding, I used the lathe as a rotary indexer.

The result was precise holes that aligned perfectly with those on the end caps.

A second hydrostatic test was successful, and the ox tank was validated to 1200 PSI, 1.5x the MEOP of 800 psi.

The 2023 oxidizer tank was further validated in cold flows and static fires, and launched in June 2023.