Related Projects: LOX Tank

Role: Responsible Engineer, Scope Owner

Duration: November 2024 – February 2025

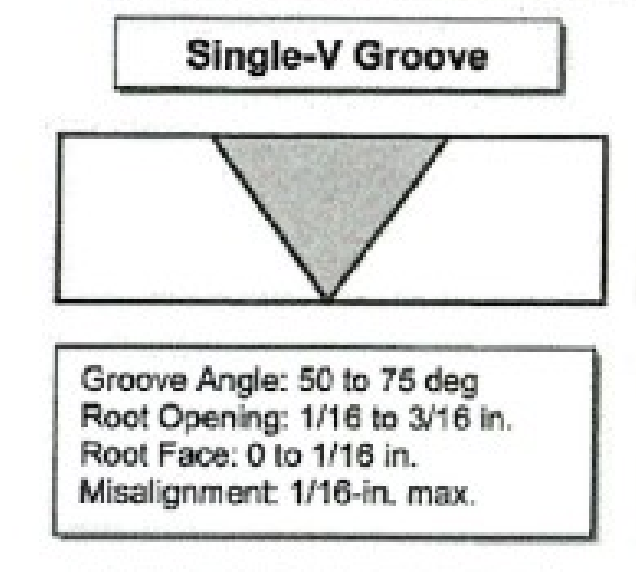

Requirements: Verify that a 6061-T6 gas tungsten arc weld with 5356 filler has a minimum tensile ultimate strength of 20,000 psi after cycling to 70 Kelvin with Liquid Nitrogen.

Objectives:

- Demonstrate a minimum burst pressure of 2.0x MEOP (1400 psi).

- Use low cost alloys and welding processes.

- Verify cryogenic sealing for static PTFE o-ring face seals.

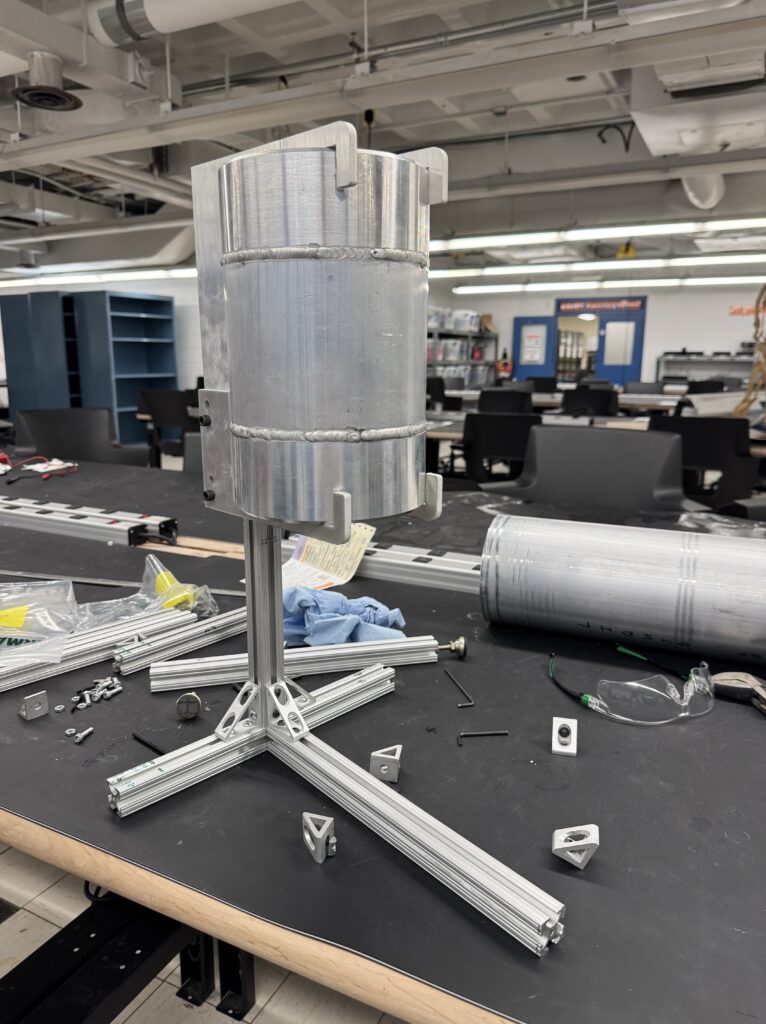

Summary: CSI Rockets had never manufactured a cryogenic welded pressure vessel before. I led the development of a weld qualification tank, which was simpler to machine and lower cost compared to the full flight LOX tank. After machining and welding, the tank was hydrostatically proof tested to 1,350 psi. It was then filled with liquid Nitrogen and held for 30 minutes, before being warmed back up and hydrostatically burst tested. The tank failed at 1,925 psi due to weld porosity causing a gross leak. The demonstrated burst factor was 2.75x MEOP, above the designed burst pressure of 2x MEOP, and gave us the confidence to proceed with flight tank manufacturing.

Result: Qualified the pressure vessel design and welding method, verified cryogenic PTFE o-rings for static sealing.

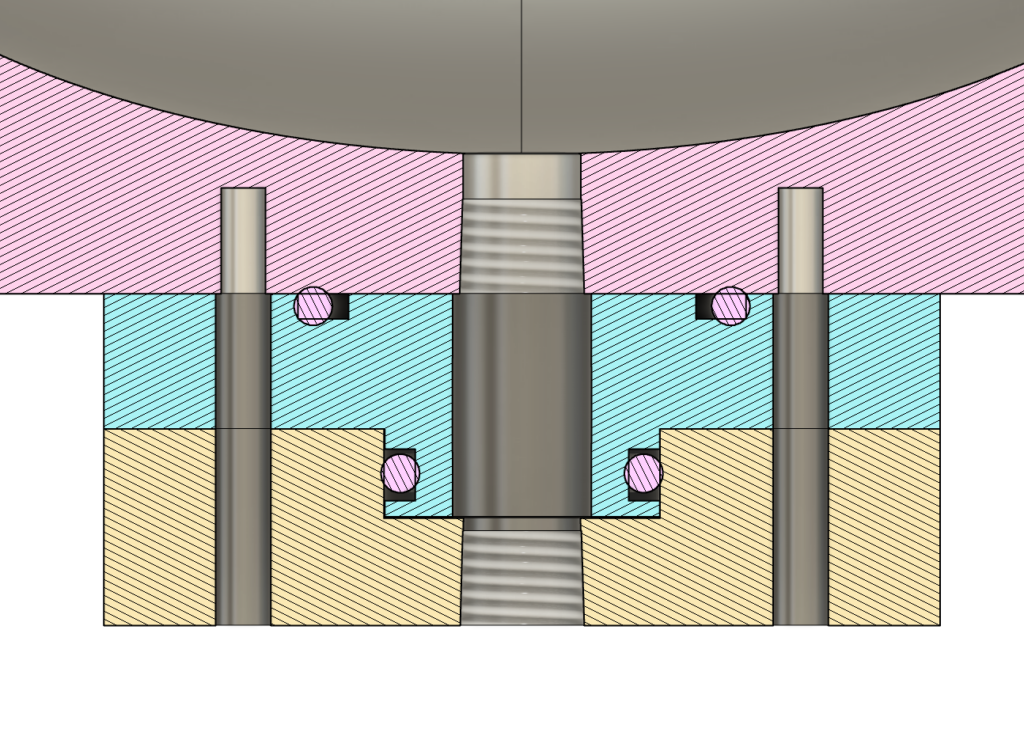

Simplified assembly drawing

I also identified an additional opportunity to test static seals for our valves and injector. The cryogenic valves use PTFE spring-loaded seals for dynamic sealing, but to save costs I designed 40% compression static PTFE face o-ring seals. PTFE is not an elastomer and it is plastically deformed during installation by design, but even when accounting for replacing the o-rings after each installation it was still a huge cost win.

There was some anecdotal information online that Viton could work at cryo, and Viton is an oxygen compatible elastomer, so that was tested as well to de-risk some of the internal injector seals (non-critical as it is a like-like design).

Testing showed gross liquid nitrogen leakage from the seal manifold. Additional inspection verified that the Viton piston seal failed, while the PTFE face seal performed nominally.

The qualification tank was then allowed to warm and was hydrostatically burst tested. Aluminum welded pressure vessels are well-characterized by NASA and others for cryogenic usage. 6061-T6 aluminum exhibits a 17.6% increase in yield strength at cryogenic temperatures (298K to 77K). However, for our specific welding process and parameters it was unknown how crack propagation and CTE mismatch along the weld would impact the strength of the joint after a cryo cycle. Therefore, a hydrostatic proof test was performed before the cryo test to 1.5x MEOP (1,050 psi), followed up by a burst test after cryo cycling. The qual tank exhibited a leak-before-burst failure mode at 1,925 psi, or 2.75x MEOP, due to a porosity in the weld.