Related Projects: LOX Tank, LOX Feed, Nitrous Run Valve

Role: Mentor, Scope Owner

Duration: September 2024 – May 2025

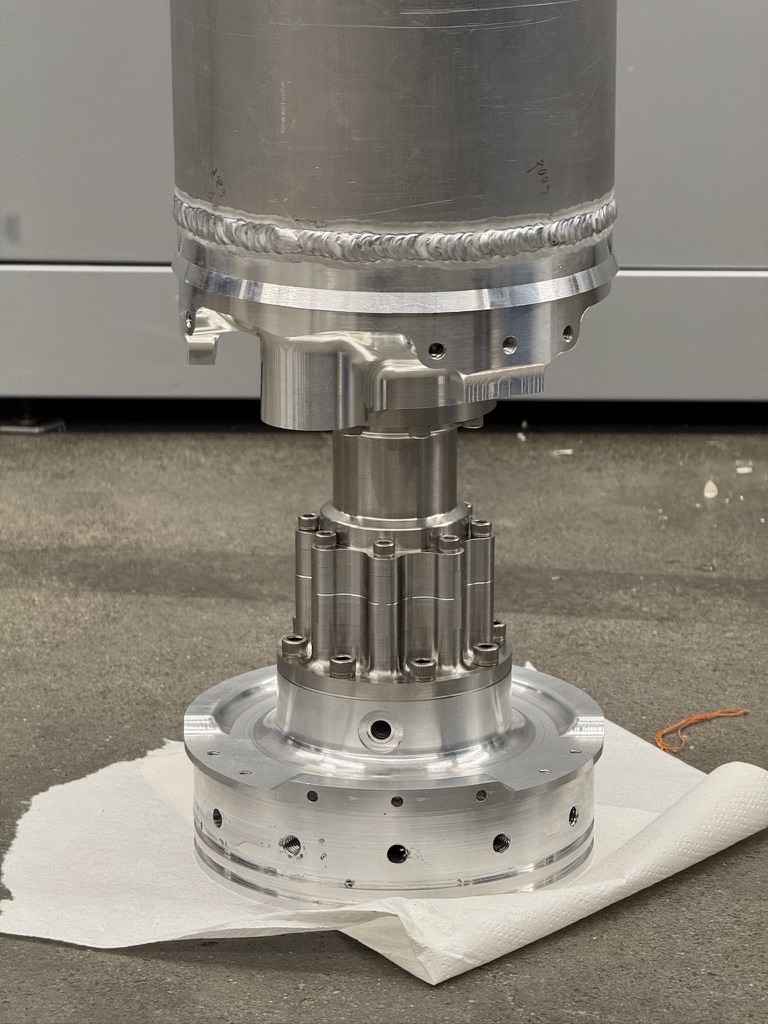

Requirements: Design a LOX run valve (main oxidizer valve).

- Actuate quickly (< 20 ms)

- Allow for 2.5 kg/s of LOX flow with < 5 psi of head loss

- Easily manufacturable on our 4-axis lathe

- LOX compatible materials

Summary: The LOX run valve was primarily designed by it’s Responsible Engineer, where I served as a mentor for the analysis, CFD, and FEA, while owning the interface and integration with other components. It uses the same coaxial design as the Nitrous Run Valve I built, however, it requires several modifications to be compatible with LOX and seal at cryogenic temperatures. See the below slides for a full design overview:

Result: After 2 months of iterative development, the valve was successfully cold flowed and supported both static fires and launch. During the development phase, I built a pneumatically-actuated ball valve that helped test other parts of the fluid system. Initially thermal contraction in the PTFE prevented sealing, and a redesign of the seal was required to ensure proper sealing.